-

Welcome! The TrekBBS is the number one place to chat about Star Trek with like-minded fans.

If you are not already a member then please register an account and join in the discussion!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

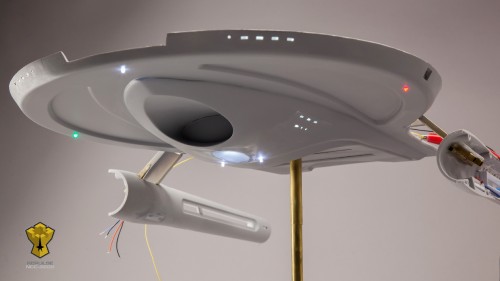

Repulse class heavy destroyer TOS design

- Thread starter AdmiralBuck

- Start date

It looks real sleek and fast! If the Hood is an american musclecar than the Repulse is a european supercar!

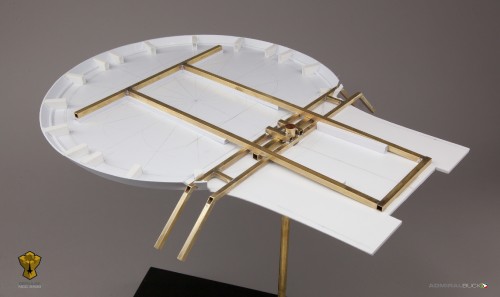

A fascinating look in how the structural arrangement is done. I was scratching my head when I saw those angled metal struts; somewhere in my head, something told me that there wasn't anything angled around there. So I went back and saw the curved hull/pylon area, "pasted" that with what I just saw, and my head went "woah, that's actually pretty nifty". Am I correct in that the aforementioned part will swoop down all the way from the aft at the impulse engines? And how will the wiring be positioned? On that little piece of cardboard (I think that's what it is) we can see in the first two shots, or inside of the metal beams?

The brass struts for the nacelles are angled - but only internally. The pylon 'shells' that will cover them will hide this elbow. The pylon shells will extend all the way to the aft corner of the hull in a continuous arc. Repulse is entirely plastic, brass and cast resin. No cardboard. The wire harness for the nacelle will run between the struts.

Do you braze the brass parts together?

Do you braze the brass parts together?

No, they are simply soldered.

This is avery nice design. I see you rough modeled it in SketchUp and I would love to try my hand at modeling it.This is my first post here so I hope I'm doing this right and posting in the right place.

I'd like to share my current project. As a model builder, I like to create original models from my own designs. Usually working from 2D line drawings, I've recently been exploring 3D as a way to help pre-visualize my concept. The Repulse heavy destroyer is a late-TOS era companion ship to my USS Sentinel light cruiser which I recently completed in 1:350 scale. This ship will be 3D printed.

As with most of my ship projects, everything is designed - from the uniforms, shuttlecraft, insignia, deck plans, and crew casting:

This is avery nice design. I see you rough modeled it in SketchUp and I would love to try my hand at modeling it.

Be my guest. May I have a copy of it when you've finished?

Of course.Be my guest. May I have a copy of it when you've finished?

I like how you've managed to make it look TOS era without it looking like a kitbash.

This is really cool. From some angles, I'm vaguely reminded of a Maquis raider, and that dovetail is reminiscent of the Excelsior, yet it's clearly a TOS vessel. I'm not a fan of the elongated 'bussard' domes, but that's a stylistic matter. And I love the way you've strengthened your design with the brass tubing. Are you using one of those big, pistol-grip soldering guns? I'd love to know more about your process with designing and building the skeleton.

And I love the way you've strengthened your design with the brass tubing. Are you using one of those big, pistol-grip soldering guns? I'd love to know more about your process with designing and building the skeleton.

I use a small Benzo-matic butane micro torch for soldering the brass joints. The brass tubing is measured, cut and pinned to a cork board to hold them together as the joint is heated and soldered.

I use a small Benzo-matic butane micro torch for soldering the brass joints. The brass tubing is measured, cut and pinned to a cork board to hold them together as the joint is heated and soldered.

Thanks! That explanation sent me on a grand tour of YouTube DIY videos that consumed quite a bit of my morning. I assume you assemble the framework first, and then build the model around it -- how rigid is that framework? It's obviously tougher than fused-together styrene. Time to go review your other threads, I think!

Thanks! That explanation sent me on a grand tour of YouTube DIY videos that consumed quite a bit of my morning. I assume you assemble the framework first, and then build the model around it -- how rigid is that framework? It's obviously tougher than fused-together styrene. Time to go review your other threads, I think!

Welcome to my world of DIY youtube! Sorry, I hadn't posted much progress pics here as this isn't typically a physical model forum. Yes, the brass frame was assembled first, with the plastic and resin hull components built around it. It is very sturdy, lightweight and allows for a place to mount it, light it and keeps everything aligned.

Last edited:

Actually, when I started in this board, the vast majority was physical model stuff. Very little 3D. It has changed to the opposite, but people still post physical models. Please don't think that those of us with little talent (in my case for both physical and 3D modelling) don't appreciate the work put into a physical model. Keep posting!

Similar threads

- Replies

- 87

- Views

- 20K

- Replies

- 482

- Views

- 59K

Contest: ENTER

September 2025 Art Challenge - Suggest Your Themes!

- Replies

- 4

- Views

- 8K

If you are not already a member then please register an account and join in the discussion!