Saquist

Commodore

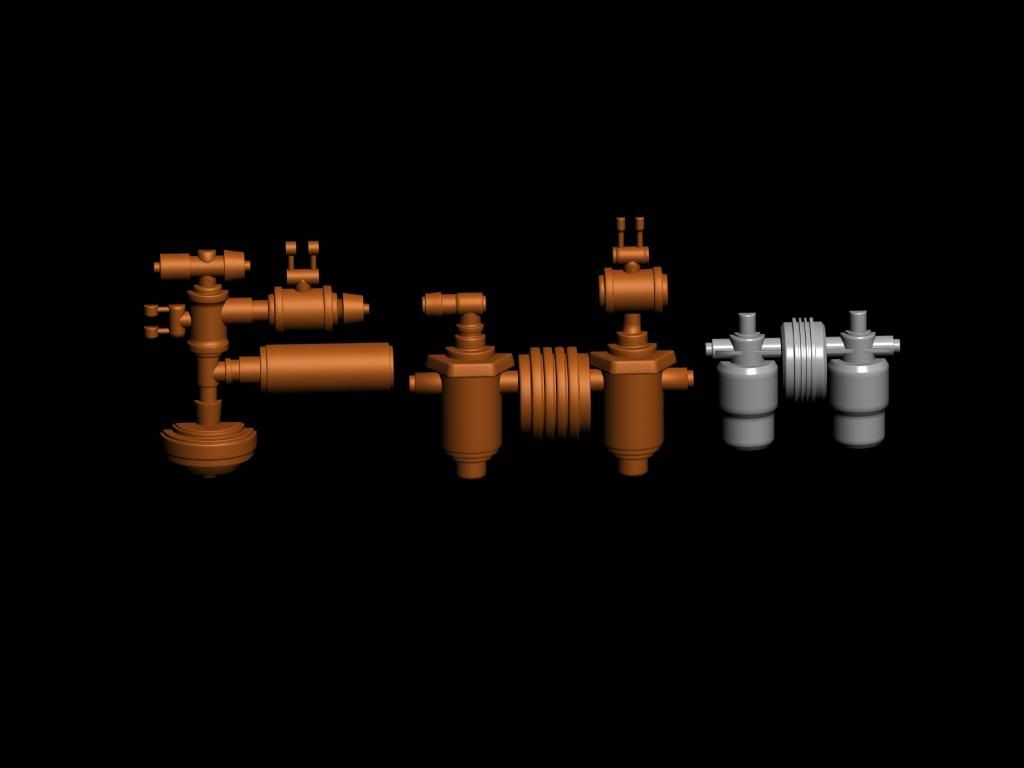

Seeing this is really helping me to appreciate what I could do to change the Constitution's design to make it more realistic and perhaps even a better looking ship. I really believe Shape should follow function and this might be an interesting part of the ship that could be altered to better suit it's needs.

I always felt the base of that neck need alot more girth in width for the loads it was carrying.

-----

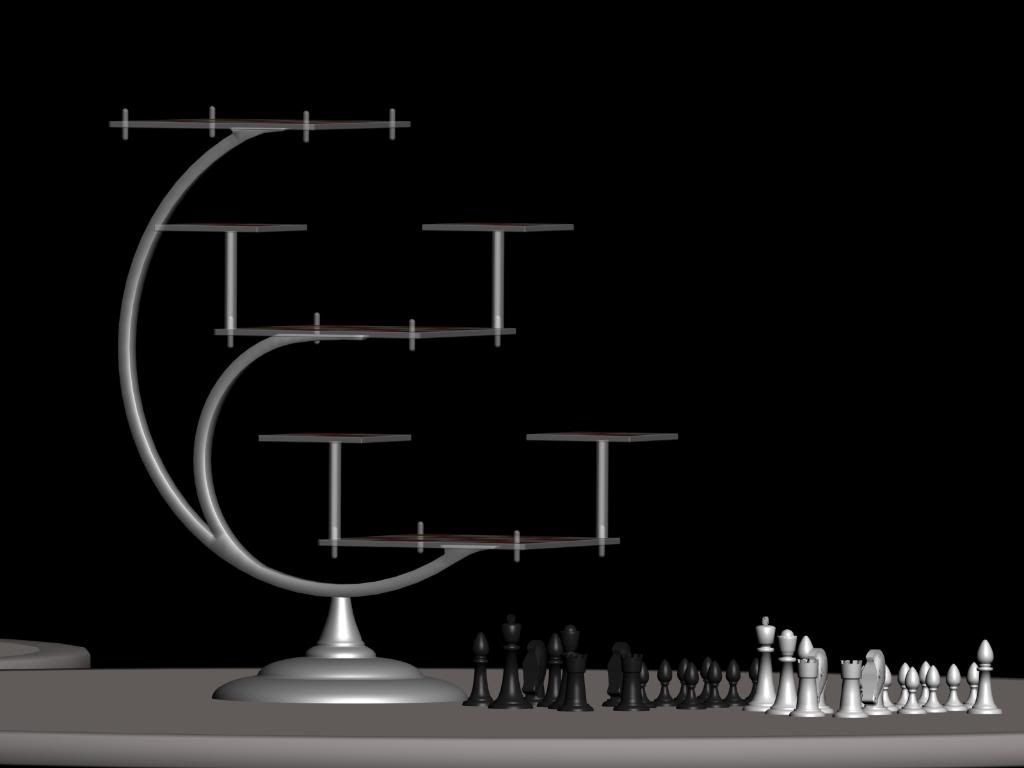

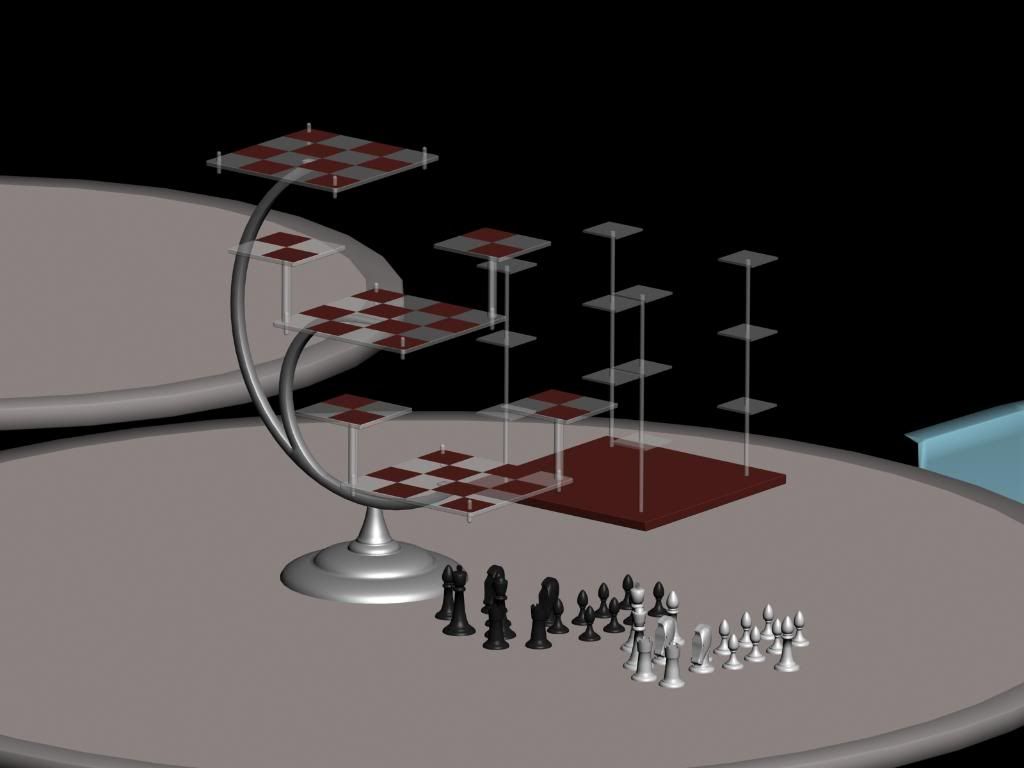

While keeping to the Consitution current form... I envisioned something like this.

I always felt the base of that neck need alot more girth in width for the loads it was carrying.

-----

While keeping to the Consitution current form... I envisioned something like this.

Last edited: