Well, that's an interesting suggestion. I don't see a problem with doing exterior hull shapes that way, though I'd be disinclined to have the actual "core structure" assembled in the same way, considering just how much stress the secondary hull really has to carry during extreme manuevers.Cary L. Brown,

I'm noticing the secondary hull has a series of annular rings around various sections. Could this imply a modular construction. A series of sections all pre-fabricated then slapped together like the way they join an aircraft fuselage during construction?

The saucer, from what David Shaw mentioned on his thread showed the pressure-hull diagram for the saucer and it looked like it could be constructed in a variety of pre-fabricated segments then slapped together too.

That would make construction incredibly efficient and fast, and could be quite useful for large refits.

CuttingEdge100

David's take, which I like, is that the primary hull is subdivided into "pressure compartments." I'm not sure if he's talking about building separate sections in different locations and strapping them all together, though. I get the impression he's thinking more in terms of how contemporary shipbuilding is done... where if you "hull" a portion of the ship, the other portions retain their environmental (and structural) integrity. If you build it as I think you're suggesting, I think you'd be compromising the overall strength of the structure.

A better model might be to look at a large ocean-going vessel. There are individual compartments, with watertight doors, throughout the ship. But there are also ... I can't recall the correct term here, so I hope someone else will chime in... but certain walls which are VERY heavy, reinforced, typically double-walled and double-hatched. The idea is that if one section of the ship is damaged, and even floods entirely, the remainder of the ship can still function.

I know that David is working from the "Pressure compartments" diagram. I don't believe that he's assuming that each pressure compartment was built in a different location and then "bolted together." And I'm certainly not presuming that, in any case, though I do like the idea of certain "watertight" sections of the ship being effectively independent from others.

(David, want to chime in on this? I don't want to misstate your position.)

As I see it, each of those regions can be sealed off and has its own local life-support system, which can't be lost if adjacent pressure compartment is compromised. (Again, this is one of my gripes with the nuEnterprise... particularly in the engineering section, but generally throughout the ship as we've seen it so far. There's no sign of "compartmentalization," whereas the TOS ship had clear indications of that (the trapezoidal "section doorways" you'd see in certain places, I always assumed were locations for section-isolation hatches).

I do like the idea of the hull being assembled in subelements, then those being assembled into the complete structure later. That's very much a parallel to how real vessels... particularly aircraft... are manufactured.

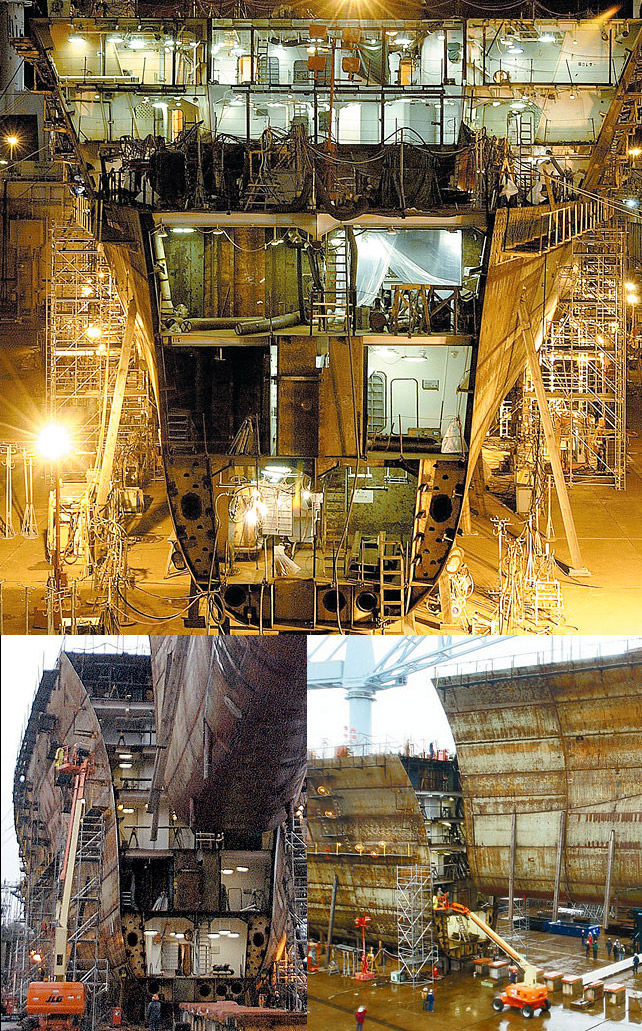

For instance, look at a large jetliner. While the midbody (including the primary wing spars) is not constructured in that sort of fashion, the remainder of the (lower-load-bearing) fuselage segments are built in exactly the manner you describe. For example, see this:

So I have no problem with that sort of construction technique being used. I'm a lot less sanguine about it being used for primary load-bearing elements, and I'm certainly not in favor if it being a "bolt-together-like-tinkertoys" approach, unless that's in a region that has no real load-bearing capability whatsoever.

There are several regions on the ship which meet that definition quite well, by the way. The actual hangar-deck portion of the ship carries no load other than that created by its own mass. Similarly, the uppermost and lowermost portions of the primary hull should be easily swapped out (and is, in fact, the reason I've adopted for the "concentric rings" on the underside primary hull). And since the deflector sees similarly low loading (except for pure-compressive loads which would be transferred, in my approach, directly into the secondary hull "keel" structure) it could be swapped out very easily as well.

What does this mean re: your suggestion? Basically... that the secondary hull "keel" and "strongback" elements cannot be compromised, and once the secondary hull "shell" elements were assembled, it would be a massive undertaking to strip them out (effectively requiring them to be ripped out wholesale). Just like you can't simply pop out a segment of a 747 once integrated.

That's my take...