Here is the thing that one should keep in mind when considering the measurements of the Enterprise... she is more sculpture than anything else.

Lets look at one single part of the model as a

for instance here... the tear-drop structure on the top of the primary hull.

What do we know about this piece of the model? Well, it is made of wood, originally a solid piece. It was based on the curves on the original Jefferies plans and should be 4 times the scale of the plans and the same structure on the 33 inch model (made a month earlier).

In December of 1964, how does one convert a curve on a drawing to something 4 times the size of the original? There are a few techniques available, but I would guess that they had a

pantograph available to them.

Still, the shape is irregular. Odds are that the block of wood that they started with was originally some dimensions made up of nice measurements... but wouldn't end up in nice measurements after the carving and sanding was done in an attempt to match the drawn curves. You end up with a lot of human imperfections in the final dimensions of that piece.

And perfection wasn't the primary goal, finishing was. The one shot the model was needed for (the crane zoom in on the bridge set) had been shot on November 30th, and they needed a model to match that footage up with. The 11 foot model was started on December 8th and finished on December 29th. That gave three men (Richard Datin, Mel Keys and Vern Sion) three weeks to build that model.

Many of the measurements are not nice because of this. Another example is the primary hull, which is not a perfect circle, and is not exactly 4 times the size on the original drawings (or the 33 inch model).

It is a work of art and it is a credit to the near Herculean undertaking of her builders. And in a study of her, in many places you aren't going to find measurements that turn out to be nice numbers... no matter what units you use.

Again, all of this needs to be put into context... and not everyone is looking at this type of thing the same way. For me, this is a documentation of an important part of history, so all of these things play a role. For others, everything I just detailed is a massive waste of time,

just round off to the nearest nice measurement and move on. I'm not expecting everyone to look at this the same way I do, though it would be nice if people did stop for a moment to reflect on these aspects (which, if you are still reading, you already have

).

This is all true... but not every bit of it is sculpture.

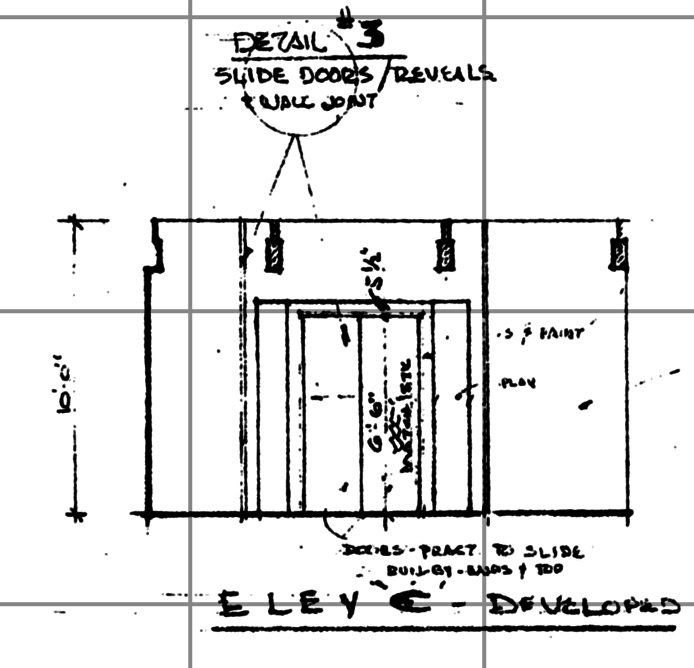

For instance, the primary hull is a wooden framework with vacuum-formed plastic skin. (The TMP one was very similar... except an aluminum frame).

When they made the primary hull, most likely they made a "template" which was a single cross-section portion of the shape, then duplicated it (as likely as not, from plywood, using a band-saw and sandpaper to clean up!). They'd have made a couple of big plywood-sheet disks to "string up" those pie-wedge panels onto, and they lay the skin over that.

Am I incorrect about any of that? I've never actually gotten to disassembled the Anderson model, after all... very few people have... but this is my understanding of the construction.

Those main elements... the flat "pie-wedge" pieces, the big disks, etc... they'd be cut to a specific size, based upon the tools available in the shop where the work was being done. And for consistency, the guys doing the work would, again as likely as not, simply set their tools to the closes "index mark" on their scale.

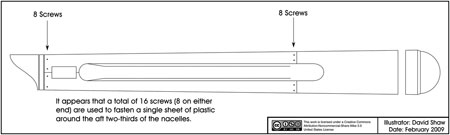

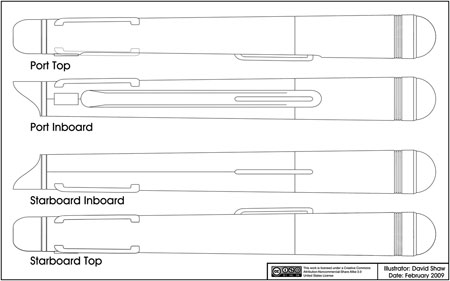

For the secondary hull and nacelles, those were made differently... turned from large wooden solids. For this reason, we should expect them to be symmetrical around the axis of the shape, not "artistically curved"... in other words, every section should be effectively circular, and every circular section should share a common axis. (This is also preferable from a real-world mechanical standpoint, as the "lowest energy" shapes are always symmetrical, and any assymetricality means that the structure is going to be more heavily stressed, and more likely to deform, when a load is applied, all other considerations being equal).

Nobody is "disregarding" what you've said, David... it's all very relevant and worthwhile. Believe me, I love seeing the "vast Shaw archive of research" as much as the next guy.

But this model was created in a real workshop using real tools and as such I'd have been surprised if it hadn't been manufactured in such a way that the shapes were best-matched to the little index lines on the lathe. (Hey, this is in the days before CNC machining, remember!)

When I see things match up, "in scale," to where I'd expect them to be in a real, machined product... it says one of two things. Either (1) this is accurate and represents the real object as made, or (2) the guy who did the drawings made assumptions about how it was made, but the real object was made in a more complicated and less straightforward fashion.

As far as the "teardrop" goes... yeah, I've never seen two "versions" of this which looked alike. And I suspect that the 11' and 3' models are dramatically different in that area... true?

Ultimately, you're an archivist... you're trying to record the exact condition of the real prop/miniature. Whereas, for me (for example), the 11' miniature is the "closest available approximation" of some "real" ship (yeah, yeah, it's not real... but we're supposed to believe that it is, that's what I'm saying, so please, no snide remarks from the peanut gallery!

)

For that reason, I'm fine with disregarding "minor defects" in the model... assymetricalities, droops, etc, etc... since it's "just a model," not the "real" ship that it's supposed to represent. It's just the best model we have, and the closest approximation of that "real" ship.

If something was supposed to be a certain size (say, the bridge dome) but it got "shaved down" later and ends up reduced in diameter... well... I'm perfectly comfortable with going with the original-intent diameter and treating the reduced-diameter as one of those "defects." If the B/C-deck superstructure is shaped in a slightly "lumpy" fashion, I'm willing to chock that up to the short production schedule... that's why I've got a "teardrop" that doesn't match ANY of the existing versions, but instead is a mathematically-correct conic shape (something that Anderson and Co would never have been able to make in the compressed timeframe that they had... just as you describe!)

Both approaches are valid... and neither is "dismissive" of the other... not inherently so, at least.

).

).

)

) ).

).