KirkTrekModeler

Commander

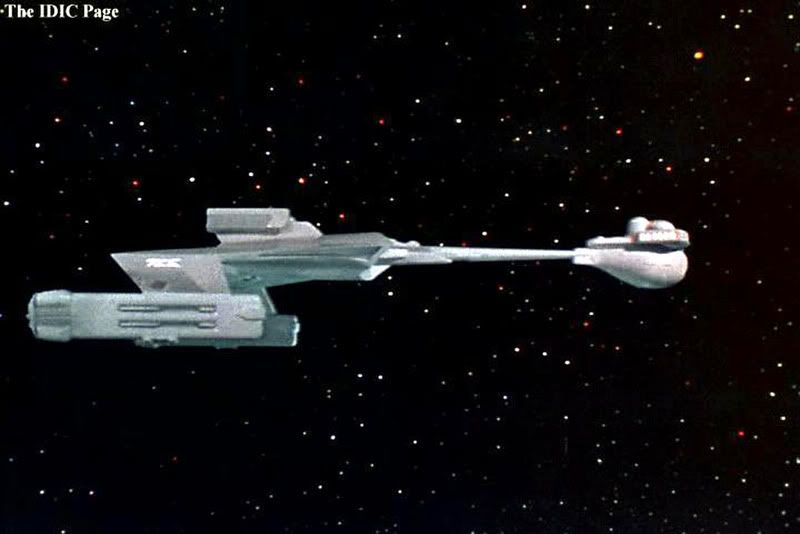

When I originally began work on the 1/350th Enterprise, almost a year ago, I started the thread out by saying that not only would I build a scale model, but that I would show *you* how to do it.

I've been a member of a forum that's primary devotion is to scratch building starships, for some time and thought I would bring some of what I've learned, over the years, to this forum and show a ground up scratch build.

I have a project that I'm begining now and thought this would be a great opportunity to share the wealth, so to speak.

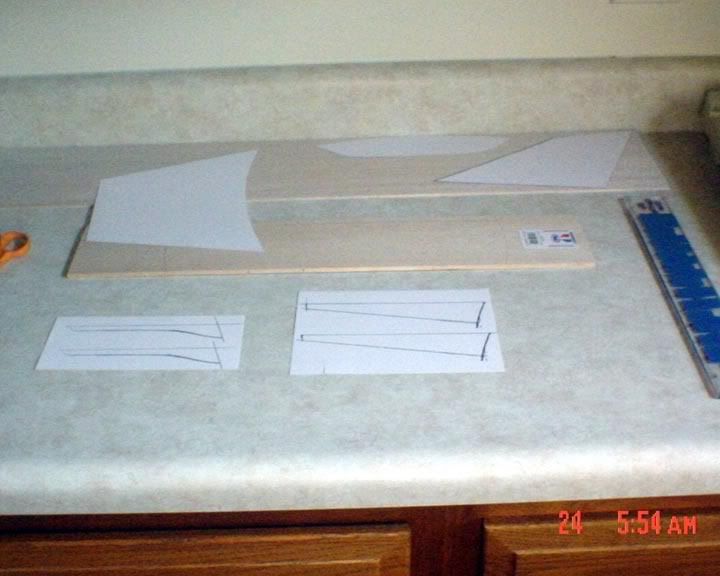

Essentially this would be a follow along build-up showing the entire process from begining to end and you could follow along and build one up as well.

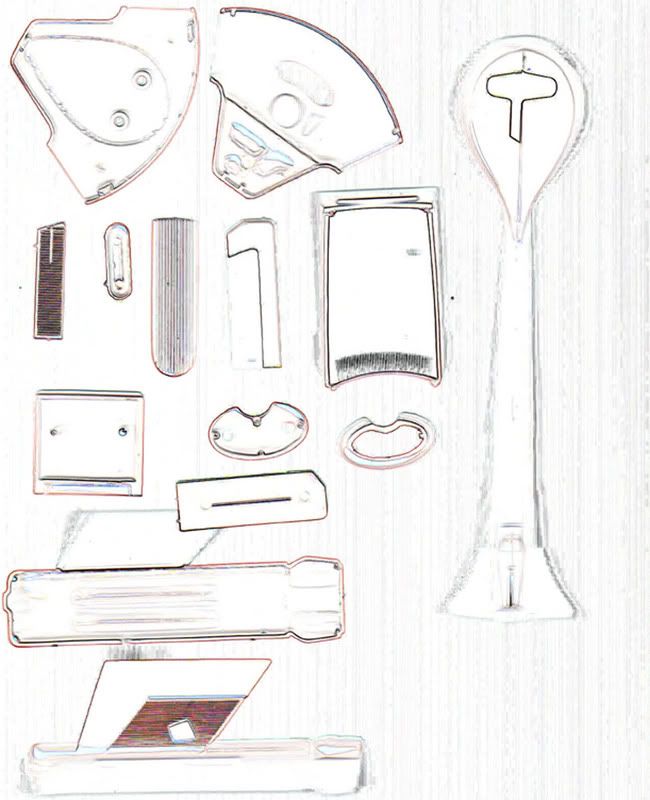

Is there any interest in this? When I did the 1/350th Enterprise, I tried to break everything down and use the cheapest available products, to show that there's more than one way to skin an Enterprise and to show that you didn't need a lot of fancy equipment, or expensive tools, or machinery and that you can start simple and still get the desired results.

The Enterprise project went through a lot of changes and was needlessly delayed, for reasons that were totally out of my control, but the original masters were made in only a couple of weeks.

Would there be continued interest in someting like this?

I've been a member of a forum that's primary devotion is to scratch building starships, for some time and thought I would bring some of what I've learned, over the years, to this forum and show a ground up scratch build.

I have a project that I'm begining now and thought this would be a great opportunity to share the wealth, so to speak.

Essentially this would be a follow along build-up showing the entire process from begining to end and you could follow along and build one up as well.

Is there any interest in this? When I did the 1/350th Enterprise, I tried to break everything down and use the cheapest available products, to show that there's more than one way to skin an Enterprise and to show that you didn't need a lot of fancy equipment, or expensive tools, or machinery and that you can start simple and still get the desired results.

The Enterprise project went through a lot of changes and was needlessly delayed, for reasons that were totally out of my control, but the original masters were made in only a couple of weeks.

Would there be continued interest in someting like this?