-

Welcome! The TrekBBS is the number one place to chat about Star Trek with like-minded fans.

If you are not already a member then please register an account and join in the discussion!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

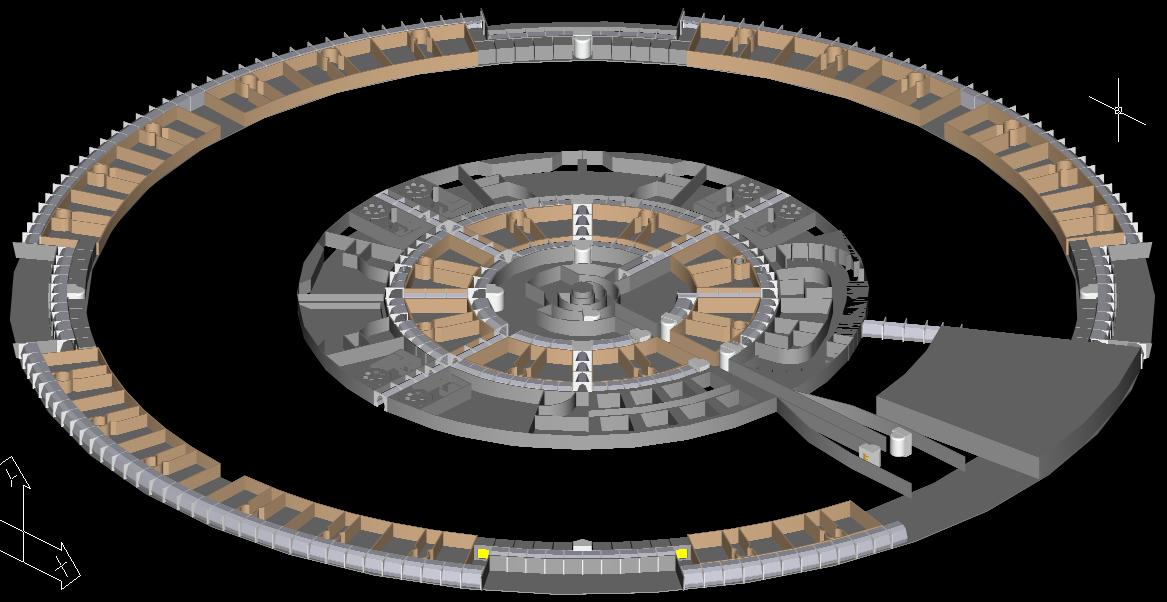

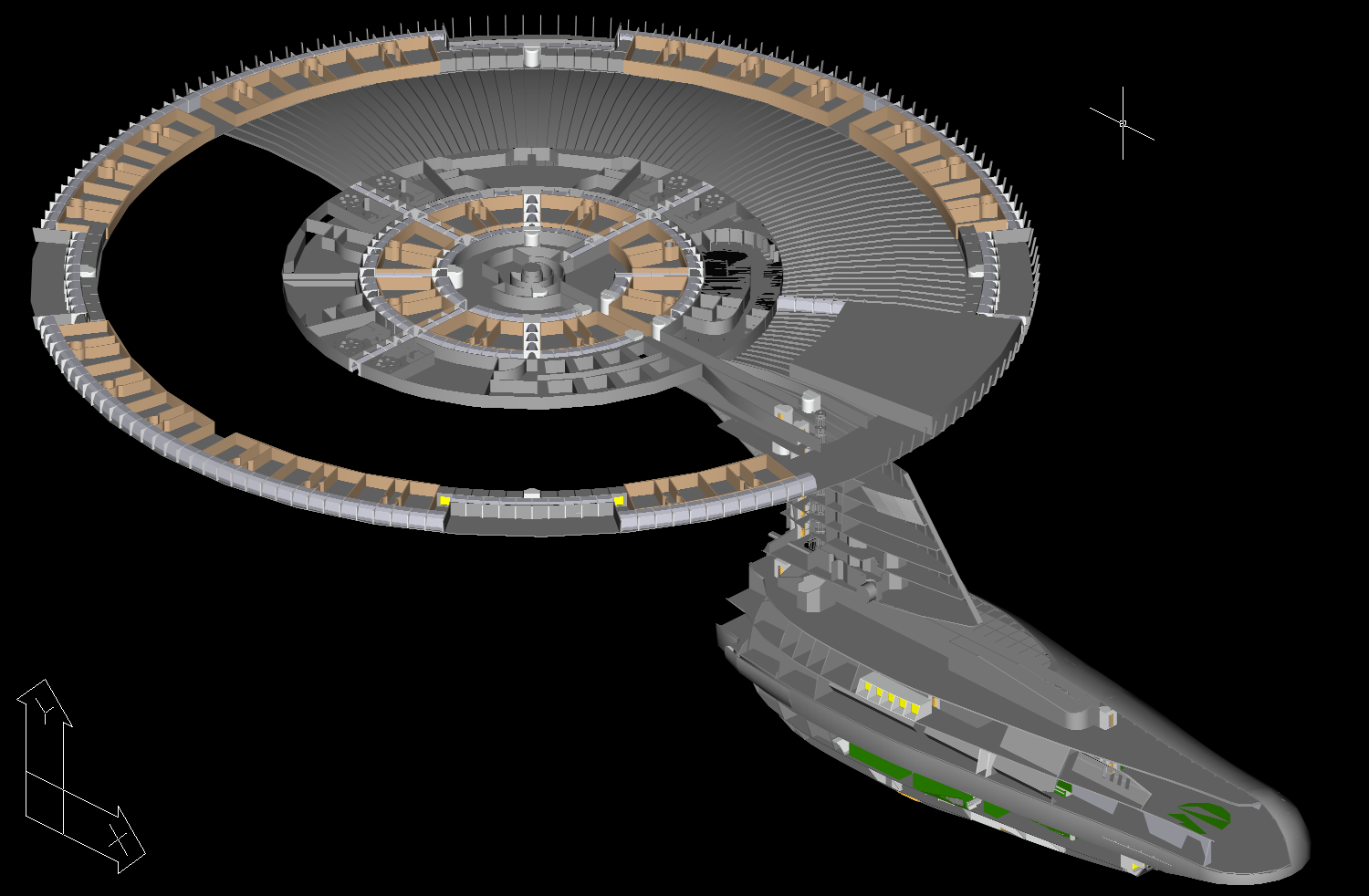

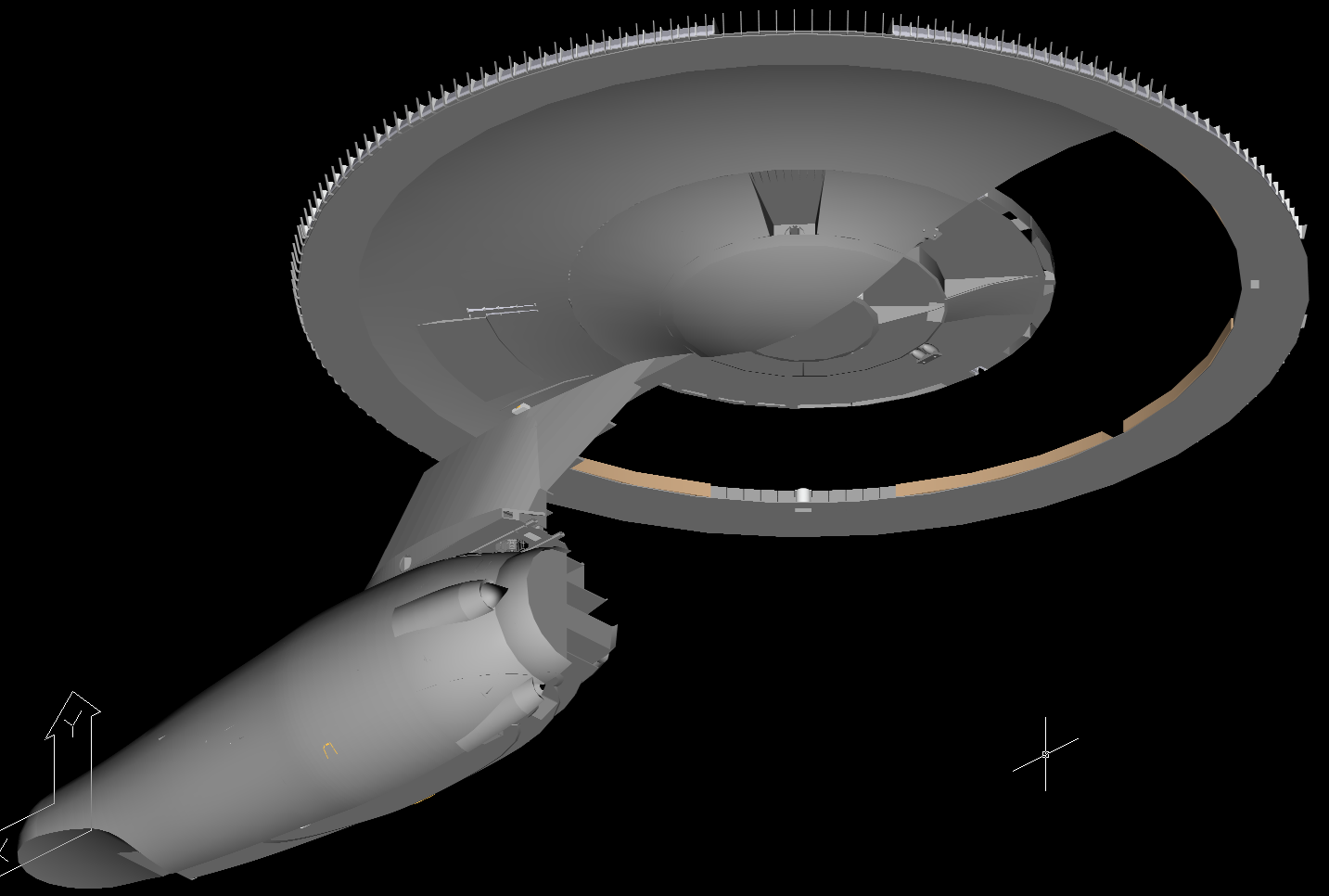

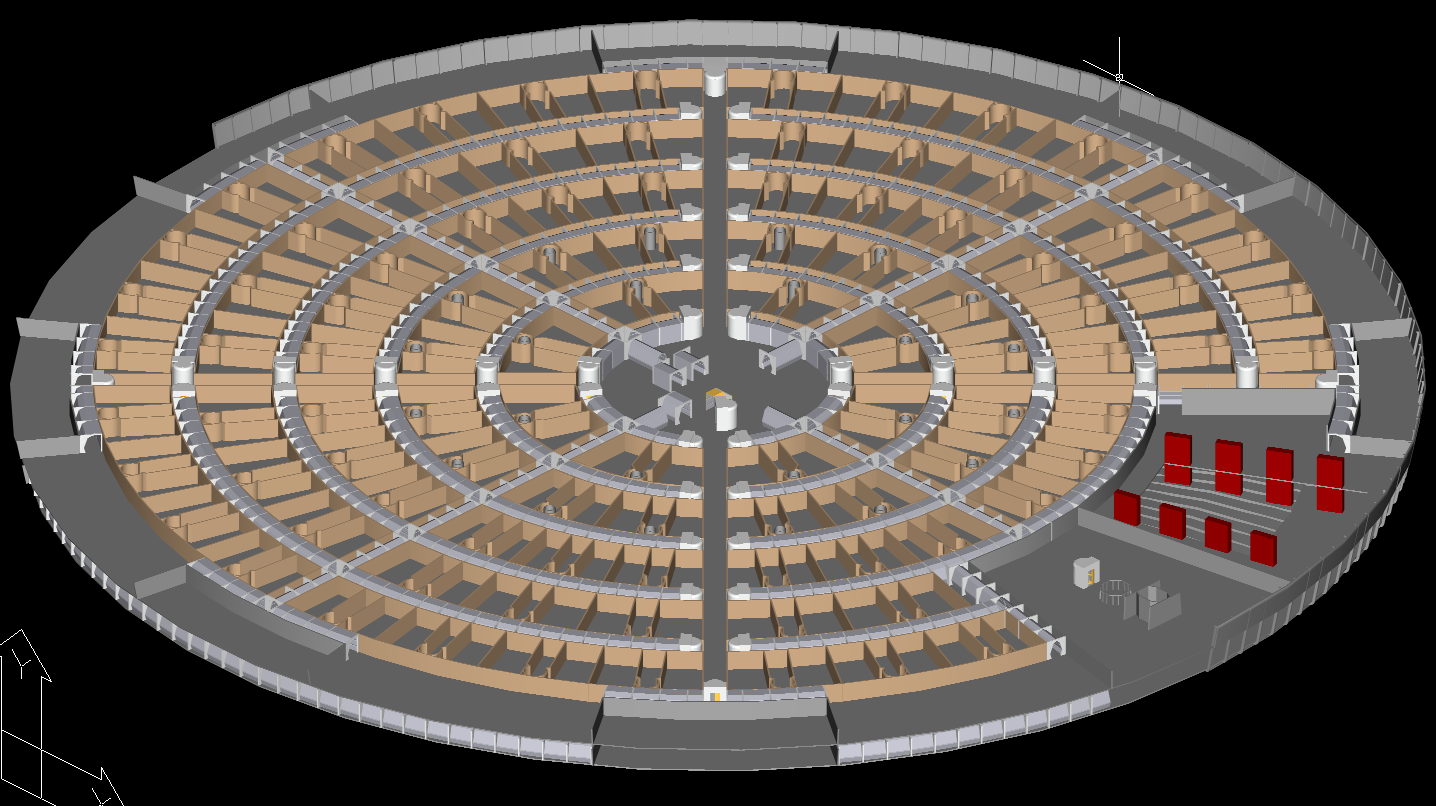

WIP - TMP Enterprise, deck by deck

- Thread starter CTM

- Start date

CTM

Awesome. Is it tedious adding all the little rooms in the saucer, or is there a shortcut to making them? And, how much detail are you planning on going into once you have the overall ship in place (i.e. beds, desks, bridge details, a few people)?

We will pay you in praise for your work...

Awesome. Is it tedious adding all the little rooms in the saucer, or is there a shortcut to making them? And, how much detail are you planning on going into once you have the overall ship in place (i.e. beds, desks, bridge details, a few people)?

We will pay you in praise for your work...

CTM

Awesome. Is it tedious adding all the little rooms in the saucer, or is there a shortcut to making them? And, how much detail are you planning on going into once you have the overall ship in place (i.e. beds, desks, bridge details, a few people)?

We will pay you in praise for your work...

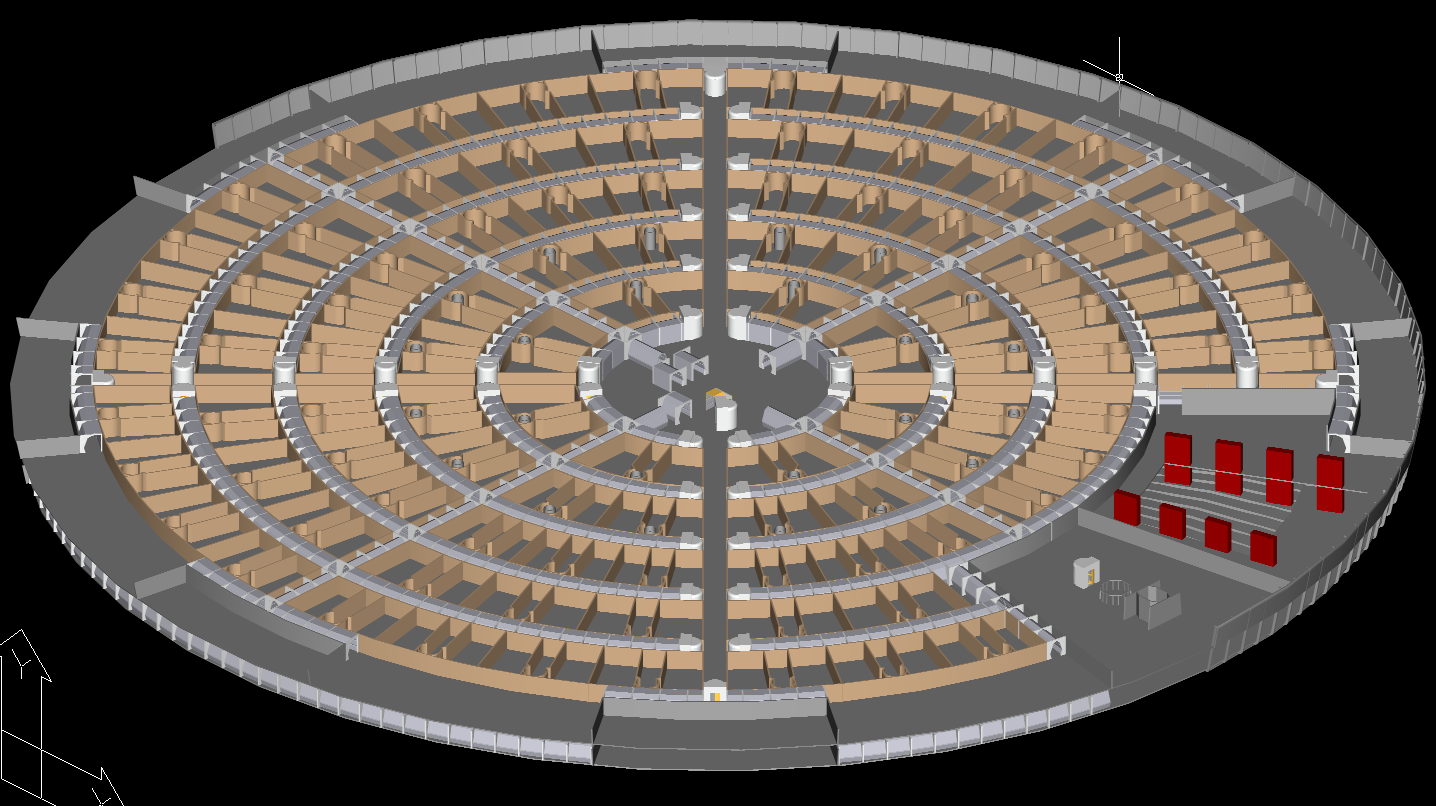

At this point, I will be happy if I can just finish the rooms and doors (if you look closely, there are no doors on most of the rooms)

Nothing is fitting together like it should. This can become quite frustrating at times. The file is starting to expand in size rapidly. For months I was at about 98MB, it's now at 197MB (not that my new system can't handle it though). The whole project is becoming unwieldy even with a beast of a system to process it. I also have other projects that are backing up, that I need to get to (some even from paying customers), but I can't seem to stop myself on this project for long.

Fortunately, this is the single most complex deck, F-deck is largely quarters, as are most of the smaller decks above F. I can start to see light from the other end of the tunnel. The only major obstacles remaining are the Impulse Engines and the Rec Deck (also the fitting/mounting of the Warp Engines, but that will be about the last thing I do on this project).

I know this might show my drastic ignorance on the subject, but does AutoCAD allow for object "instances"? That is, instead of copy/paste and increasing your object count, you would have a single object, instantiated in multiple locations - that way, you would only have multiple "pointers" to a single point in memory for multiple repeating objects (corridor segments, transporter rooms, crew quarters, etc.), taking significantly less RAM. It's a pretty common programming concept, particularly in the object-oriented world, but I was curious if AutoCAD had a similar feature to help cut down the size of runaway files like this one. Just a thought. You can tell me to shut up if I'm talking out my ass on this one.

I know this might show my drastic ignorance on the subject, but does AutoCAD allow for object "instances"? That is, instead of copy/paste and increasing your object count, you would have a single object, instantiated in multiple locations - that way, you would only have multiple "pointers" to a single point in memory for multiple repeating objects (corridor segments, transporter rooms, crew quarters, etc.), taking significantly less RAM. It's a pretty common programming concept, particularly in the object-oriented world, but I was curious if AutoCAD had a similar feature to help cut down the size of runaway files like this one. Just a thought. You can tell me to shut up if I'm talking out my ass on this one.

It does (kinda), and I use that extensively, but there are enough subtle differences in most places that objects are "similar" but not "identical" so I wind up having to create a unique instance of an object. The corridors, for example. There are the two types: Radial (angled panels on both sides) and concentric (angled panels on one side only). The joints between segments are objects, they don't change from one to another. The concentric corridor segments, however, have to be cut to fit at the correct angle for each corridor. The radial ones have to be cut to fit in the hall length (not as often, but they do from time to time). I could probably use more object dropping instead of unique building, but it winds up as six of one, half a dozen of the other. The other problem is, when I insert a block (AutoCAD object), it instantiates the whole block - not just an object reference, so it makes almost no difference in size/performance (AutoCAD 2000 might do better at it, I have not experimented with that in this version yet).

Would it be possible to separate it into assemblies and components at this point? For example, making each deck its own file, and having another that assembles them all together. That way, you'd only have to load the deck you're working on and maybe the one above and below for reference.

That's largely why I've gone with "vertical-only walls" throughout my own stuff. I can simply sketch the wall outlines on the floor and extrude up to the ceiling. Well, technically I extrude to the "next surface encountered," which allows for inwards-sloping walls on the outer hull. Of course, occasionally, in regions with outwards-sloping walls I have to do an extrude from the ceiling downwards to the "next surface". But it's still a lot easier than doing the complex corridor shapes you're doing there, and captures "almost as much" information about the internal layout of the ship.CTM

Awesome. Is it tedious adding all the little rooms in the saucer, or is there a shortcut to making them? And, how much detail are you planning on going into once you have the overall ship in place (i.e. beds, desks, bridge details, a few people)?

We will pay you in praise for your work...

At this point, I will be happy if I can just finish the rooms and doors (if you look closely, there are no doors on most of the rooms)

Nothing is fitting together like it should. This can become quite frustrating at times. The file is starting to expand in size rapidly. For months I was at about 98MB, it's now at 197MB (not that my new system can't handle it though). The whole project is becoming unwieldy even with a beast of a system to process it. I also have other projects that are backing up, that I need to get to (some even from paying customers), but I can't seem to stop myself on this project for long.

Fortunately, this is the single most complex deck, F-deck is largely quarters, as are most of the smaller decks above F. I can start to see light from the other end of the tunnel. The only major obstacles remaining are the Impulse Engines and the Rec Deck (also the fitting/mounting of the Warp Engines, but that will be about the last thing I do on this project).

Of course, I really prefer vertical walls anyway. They're simply more practical, both ergonomically and mechanically. They're not as "visually interesting," I'll grant... but the ONLY place I've ever seen non-vertical-walled corridors where it made sense was in "The Andromeda Strain," where the circular-sectioned corridors had been manufactured by drilling through solid rock. All things being equal, vertical walls would still be preferable, but I'm sure "Wildfire" was expensive enough as it was... no need to "Square off the walls" and end up skimping on lab equipment!

You're right, though... the approach you're taking makes good sense. If it were ME doing it, I'd leave off the detail and go with plain rooms and vertical walls only except in locations where the details can be seen through windows.

You can go really nuts with this stuff, but it WILL eventually "kill your system." I had to put the 1701 on-hold, and that's not the first time I've had to do that. After this weekend, my new system will be able to run (I HOPE) so I can get back to work again. I'm starting to get motivated, but honestly, I'm starting to get more motivated towards restarting on the Vega than on the 1701... did you ever see the Vega class? It's the ship in my avatar. I won't post the images here, but if you're interested, check these two animated GIFs out.

http://img176.imageshack.us/img176/1909/animation5ch0.gif

http://img341.imageshack.us/img341/833/animation4nu8.gif

It's a pretty common programming concept, particularly in the object-oriented world, but I was curious if AutoCAD had a similar feature to help cut down the size of runaway files like this one.

Yes it does, it is called Xref.

It does (kinda), and I use that extensively, ..... The other problem is, when I insert a block (AutoCAD object), it instantiates the whole block - not just an object reference, so it makes almost no difference in size/performance (AutoCAD 2000 might do better at it, I have not experimented with that in this version yet).

The reason why it does not make no difference in size and the reason why it instantiates the whole block, is simply the fact that blocks weren't invented for this reason of object reference. They were invented to change lots of objects at the same time. For example, if you inserted a thousand doors, you could change them all at one time, and have a door with a window or other color or whatever. If you need an object reference so that the drawing size not increases you will have to work with Xref objects, or what is even better make Xrefs containing a whole deck. That way you can build deck by deck, and insert them into a "master" with a bitcount of almost zero. Also nice if you want to change a deck, it will automaticly be updated in your "master".

BTW, AutoCad 2000 works the same.

This is a very common practice, but as far as I'm concerned, aren't we just talking "parts" versus "assemblies," and "subassemblies?"It's a pretty common programming concept, particularly in the object-oriented world, but I was curious if AutoCAD had a similar feature to help cut down the size of runaway files like this one.

Yes it does, it is called Xref.

It does (kinda), and I use that extensively, ..... The other problem is, when I insert a block (AutoCAD object), it instantiates the whole block - not just an object reference, so it makes almost no difference in size/performance (AutoCAD 2000 might do better at it, I have not experimented with that in this version yet).

The reason why it does not make no difference in size and the reason why it instantiates the whole block, is simply the fact that blocks weren't invented for this reason of object reference. They were invented to change lots of objects at the same time. For example, if you inserted a thousand doors, you could change them all at one time, and have a door with a window or other color or whatever. If you need an object reference so that the drawing size not increases you will have to work with Xref objects, or what is even better make Xrefs containing a whole deck. That way you can build deck by deck, and insert them into a "master" with a bitcount of almost zero. Also nice if you want to change a deck, it will automaticly be updated in your "master".

BTW, AutoCad 2000 works the same.

For example:

If I make a PCBA ("printed circuit board assembly") with fourteen instances of the same resistor, I simply assemble those parts into my assembly and the memory-footprint per component remains the same, while the assembly only contains the "placement" data associated with that instance.

I thought ALL CAD programs (at least, all 3D CAD programs) worked the same way.

There are also, in ProENGINEER, things called "UDFs." No, they're not birth-control devices. Rather, they're "user-defined features"... something which can be created once, then easily copied to many locations. This is popular, for instance, for repeated features like the "standoff bosses" inside of molded parts. These, however, do add to the size of the PART which they're added to.

In the case of the 1701 model I've been making, I've done my little round "sensor porthole" windows as UDFs. Instead of having to remodel them every time, I simply had to create an attachment point for each, and then attach them to a particular surface, centered on that point (which, of course, had to be on the surface in question).

I would NOT use "UDF" type features for the corridors, but I might seriously consider using PARTS in an ASSEMBLY to do this, especially if there are many repeated features.

Mind you, it doesn't change "data manipulation" times once it's in memory... transformations and rendering still depends on the total data, so every "part" takes the same this way in any case. However, the amount of regeneration, the memory footprint, and the hard-drive footprint... those are significantly reduced by reusing parts multiple times.

This is a very common practice, but as far as I'm concerned, aren't we just talking "parts" versus "assemblies," and "subassemblies?"

Yes we are.

For example:

If I make a PCBA ("printed circuit board assembly") with fourteen instances of the same resistor, I simply assemble those parts into my assembly and the memory-footprint per component remains the same, while the assembly only contains the "placement" data associated with that instance.

Yes, that is exactly what you do with XREF. Your "master" contains only the "placement".

There are also, in ProENGINEER, things called "UDFs." No, they're not birth-control devices. Rather, they're "user-defined features"... something which can be created once, then easily copied to many locations. This is popular, for instance, for repeated features like the "standoff bosses" inside of molded parts. These, however, do add to the size of the PART which they're added to.

Yes that is what CTM is doing with his blocks. But he has to do this in his subassembly. He can rework the subassemblies without having the trouble of loading his complete ship.

I would NOT use "UDF" type features for the corridors, but I might seriously consider using PARTS in an ASSEMBLY to do this, especially if there are many repeated features.

"UDF" or blocks as they are called in AutoCad, can be manipulated from outside the drawing, for example the corridors, you can change a corridor (which would be just a small drawing), and then load your subassembly, and AutoCad change the instances (blocks) at once. So yes, I would use them, but only in combination with subassemblies (XREF).

Mind you, it doesn't change "data manipulation" times once it's in memory... transformations and rendering still depends on the total data, so every "part" takes the same this way in any case. However, the amount of regeneration, the memory footprint, and the hard-drive footprint... those are significantly reduced by reusing parts multiple times.

Exactly, and working on the subassemblies without having to load or regenerate the whole model, will let you work a lot faster.

Well, I made some progress on F-deck, and I'm fairly well down to just having to finish the Rec-Deck and Impulse Engineering (on both decks), though there are some missing elements in the core area of F-Deck, and the saucer-edge docking port/air-lock/gangways.

Last edited:

WOW!

I bet you're happy this was probably a straight extrusion, huh?

I have to say I don't like the saucer layout on this one. TOO many corridors!

They could have put some of these rooms back to back or with only maintainance shafts through.

btw, the color really helps.

Yeah, I thought about that too. I also thought about my experiences with Dorm Life (college), and Barracks Life (Army). I think the more private corridors help with shift scheduling (e.g. you have Corridor X on shift Y etc.) so that everyone on a given work/rec/sleep schedule can be grouped together on the same hall. Also, it allows for better segregation by rank (Officer Country etc.). Basically, I left this deck as it was arranged by Strategic Designs. There were some alterations, but I think the spirit of the design was kept.

Around the outer ring (saucer edge) are lounges, in the core is the Mess. I figure that there are also some meeting/conference/multi-purpose rooms in between lounges. Also (except for a zig-zag around Engineering and the Rec Dec) there is a continuous loop around the outside for crew to jog/run/walk for PT (beyond a Gym all the way down in Engineering, and whatever else they might use the various multi-purpose rooms for). I have left a large area on the upper level of the Rec Dec open. I can envision a 10-forward or Quark's style bar/casino/whatever going in there, or simply more lounge furniture. I have not yet finished the lower part of the Rec Deck, which is higher than the remainder of G-deck because of the saucer under-cut.

Saquist

Commodore

Sounds good to.

The whole thing gives me all kinds of ideas for the Enigma Class.

I found that the Engineering was just as..."easy" to develop on the Enigma as on the Enterprise Class. It's the function that is required there. the Needs of the power systems, routing and storage are very clear.

I abhor to think of how I'd have to arrange crew quarters like this.

The whole thing gives me all kinds of ideas for the Enigma Class.

I found that the Engineering was just as..."easy" to develop on the Enigma as on the Enterprise Class. It's the function that is required there. the Needs of the power systems, routing and storage are very clear.

I abhor to think of how I'd have to arrange crew quarters like this.

Just found this today, was pointed in your direction ater starting a similar endeavor!

after browsing your work (and pulling out a few hairs at the "what have i gotten into" factor) just wanted to say it looks great! keep up the good work

Thank you for the kind words. Hopefully, I'll be getting back to working on it this weekend. Good luck with yours, and don't get carried away on detail - it is killing mine

Saquist

Commodore

I've sloweeed way down on my 3D too.

http://www.startrekmovie.com/forums/attachment.php?attachmentid=1679&d=1253882187

http://www.startrekmovie.com/forums/attachment.php?attachmentid=1678&d=1253882176

That's my fuselage for the stardrive. I'ts real curvy and that what you can do with the loft command.

I imagine the saucer and the neck would be relatively easy with it. (for your work)

I'm going to boost this back to the front page so as it won't get lost

http://www.startrekmovie.com/forums/attachment.php?attachmentid=1679&d=1253882187

http://www.startrekmovie.com/forums/attachment.php?attachmentid=1678&d=1253882176

That's my fuselage for the stardrive. I'ts real curvy and that what you can do with the loft command.

I imagine the saucer and the neck would be relatively easy with it. (for your work)

I'm going to boost this back to the front page so as it won't get lost

I have been rather preoccupied lately with a dying car and acqurinig a replacement, in the midst of which a neighbor bashed in my wife's car - so automobiles have dominated my life for the last few weeks - hopefully I can crawl out from beneath the latest one and get back to this project soon.

Similar threads

- Replies

- 0

- Views

- 3K

- Replies

- 0

- Views

- 309

If you are not already a member then please register an account and join in the discussion!