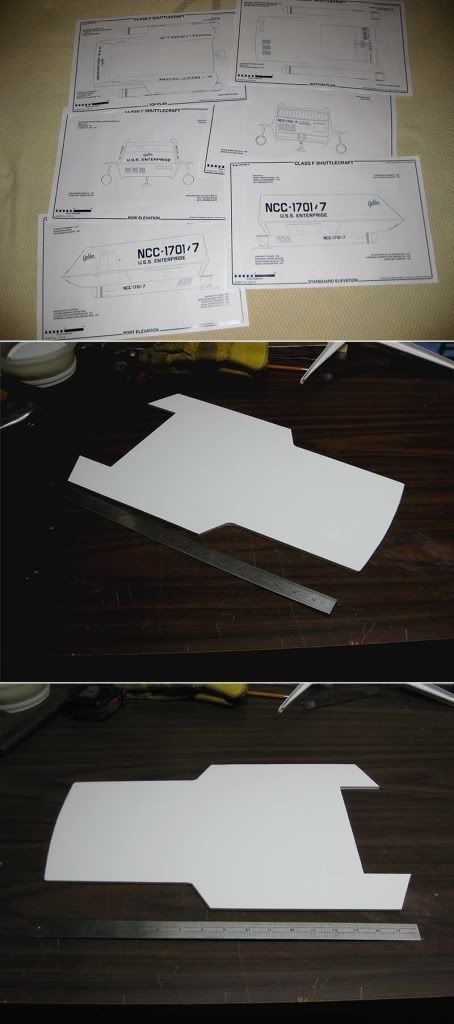

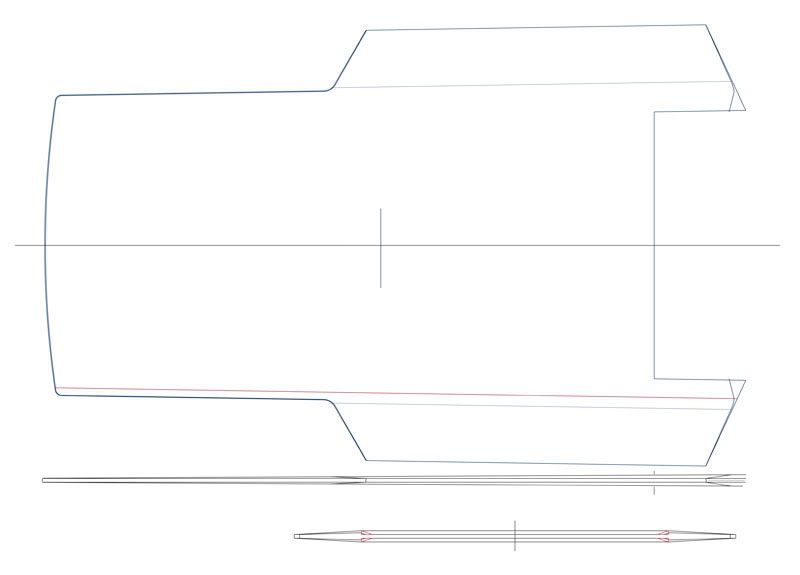

Picked up some foamcore today and should start cutting pieces soon.

Now I need some advice for down the road. How can one make a sound chip? You know some of those greeting cards that play music when you open them or toys that make sounds when you press a button. Well I know those are chips (I believe), but is it hard to make one? I have the sound effects and such of what I want as audio files on my computer and I want to know how to make my own sound chip to put into the model so when I press a button on the display stand it will play the sound effect.

The three separate audio tracks are 1:20, 1:16 and 1:15 seconds each in duration.

Anyone?

Now I need some advice for down the road. How can one make a sound chip? You know some of those greeting cards that play music when you open them or toys that make sounds when you press a button. Well I know those are chips (I believe), but is it hard to make one? I have the sound effects and such of what I want as audio files on my computer and I want to know how to make my own sound chip to put into the model so when I press a button on the display stand it will play the sound effect.

The three separate audio tracks are 1:20, 1:16 and 1:15 seconds each in duration.

Anyone?

Last edited: