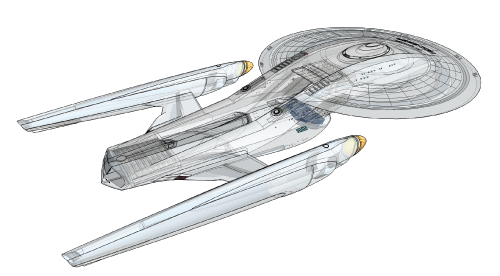

I'd put it in the early 24th center as it looks closer to the Sovereign than the Excelsior..

-

Welcome! The TrekBBS is the number one place to chat about Star Trek with like-minded fans.

If you are not already a member then please register an account and join in the discussion!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/350 scale Project: Endurance

- Thread starter AdmiralBuck

- Start date

Astounding as always. Especially those last couple of pictures. I zoomed in on the detail under the hull and found myself wondering how many times you say to yourself, "Wait 'til they get a load of this!"

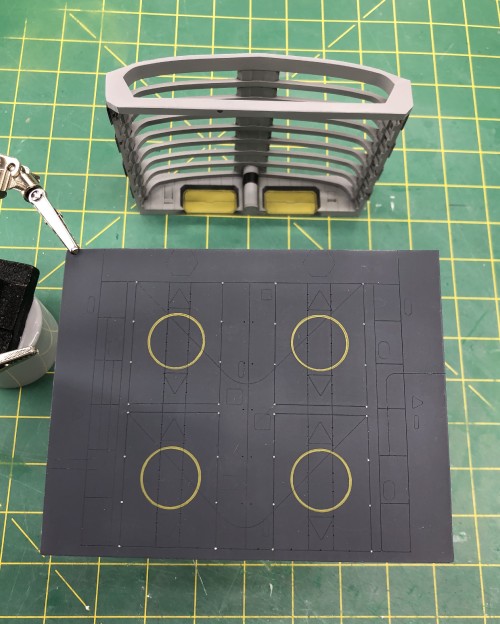

I love the sensor dome, it's very reminiscent of the Excelsior. Is this the first time you've used 3D printing in your work (for this and the shuttle bay framework)? Did you order from Shapeways or a similar agency?

I love the sensor dome, it's very reminiscent of the Excelsior. Is this the first time you've used 3D printing in your work (for this and the shuttle bay framework)? Did you order from Shapeways or a similar agency?

Thanks! No, this isn't the first model I've done using 3D printed components. I have a peer who has a very nice printer who is doing this print work for me from models I'm sending him. It's usually used for small details or customized parts specific to the design. It's been my goal to slowly work towards a fully digital printed model but there are still some things that are simply quicker and easier to do by hand.

wonderful design as are all your ships may I ask a question is their a place where I can see all your ships, especially the Blackhawk. I found the Repulse, Hood, and Sentinel thank you in advance

No, unfortunately I do not have a online portfolio other than my image hosting project folders. The Blackhawk is still a very raw concept ship but may resume later this year.

I get too much of a kick out your posts, AdmiralBuck! I wish you posted daily, but then I'd be rushing an artist, and that never turns out well.

I don't think I've asked yet: how do you secure your fiber optics? I used to smoosh 'em down with the flat chisel on a hot soldering iron -- producing a little mushroom cap easily glued in place. But I struggled with keeping the melts consistent. You seem to have a better technique.

I don't think I've asked yet: how do you secure your fiber optics? I used to smoosh 'em down with the flat chisel on a hot soldering iron -- producing a little mushroom cap easily glued in place. But I struggled with keeping the melts consistent. You seem to have a better technique.

I get too much of a kick out your posts, AdmiralBuck! I wish you posted daily, but then I'd be rushing an artist, and that never turns out well.

I don't think I've asked yet: how do you secure your fiber optics? I used to smoosh 'em down with the flat chisel on a hot soldering iron -- producing a little mushroom cap easily glued in place. But I struggled with keeping the melts consistent. You seem to have a better technique.

Aww, thanks for following the project!

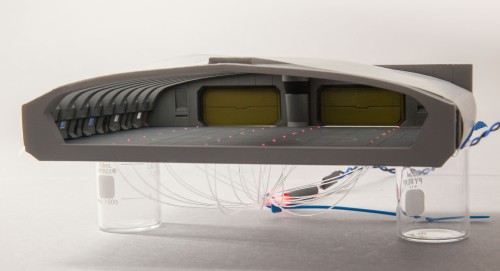

The FO are 'lensed' by tapping them lightly against the cooler end of the soldering iron, almost near the handle to keep them from melting. After inserting through the drilled hole, I'm using a white glue (Canopy Glue) to secure them in place from behind.

I love seeing all the work you put into these. So gorgeous!

Interesting to see the amount of structural support you build into this model, might not be too light to carry around but at least no saucer or nacelle will sag or break off.

Thanks! I did spend a bit of time engineering the required amount of support, both in brass and styrene to construct what needed built. These are lightweight materials so there is no concern with unnecessary weight, but structurally it is immensely sturdy.

Absolutely beautiful work. It is big. I hope you did some sort of a structural load test on your brass framework. As an engineer, I always worry about soldered joints. The design of the hull components and their fit up are fantastic. My favorite feature is the design of your shuttlebay; very realistic with large support struts and beams visible inside; plus runway lights on the deck. Can't tell if you are going to have hard shuttlebay doors and how they would work. "Endurance" across the stern is classic.

Absolutely beautiful work. It is big. I hope you did some sort of a structural load test on your brass framework. As an engineer, I always worry about soldered joints. The design of the hull components and their fit up are fantastic. My favorite feature is the design of your shuttlebay; very realistic with large support struts and beams visible inside; plus runway lights on the deck. Can't tell if you are going to have hard shuttlebay doors and how they would work. "Endurance" across the stern is classic.

Thank you. This is my eighth build with an engineered brass armature. Twice as large as any previous work, the keel mainly insures proper alignment of the individual hull components as well as internal support to its main hub. Once fully assembled, the unibody styrene hull is self supported.

Thanks for the info. By the way, where are you going to put this beast on display?Thank you. This is my eighth build with an engineered brass armature. Twice as large as any previous work, the keel mainly insures proper alignment of the individual hull components as well as internal support to its main hub. Once fully assembled, the unibody styrene hull is self supported.

Thanks for the info. By the way, where are you going to put this beast on display?

That part of the pre-planning has yet to be firmed up.

I'll take one for the team. I volunteer my house.That part of the pre-planning has yet to be firmed up.

Similar threads

If you are not already a member then please register an account and join in the discussion!