OK this is how I spent the weekend, not done yet. (I never am, hehe), but enough detail to post some images.

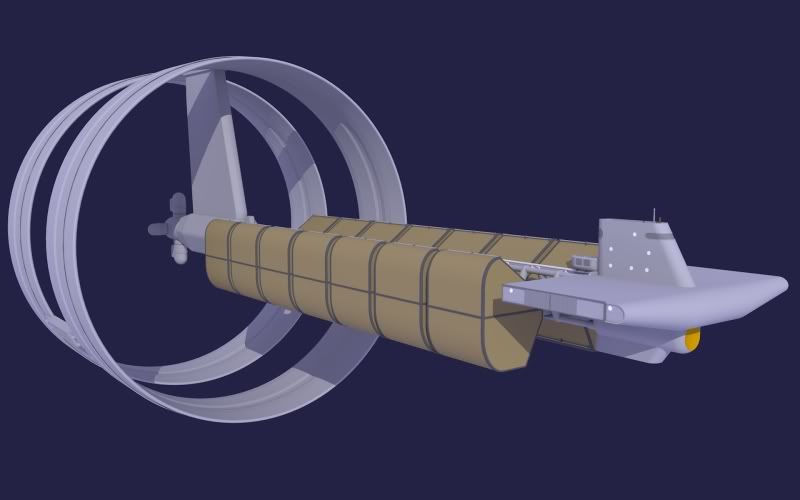

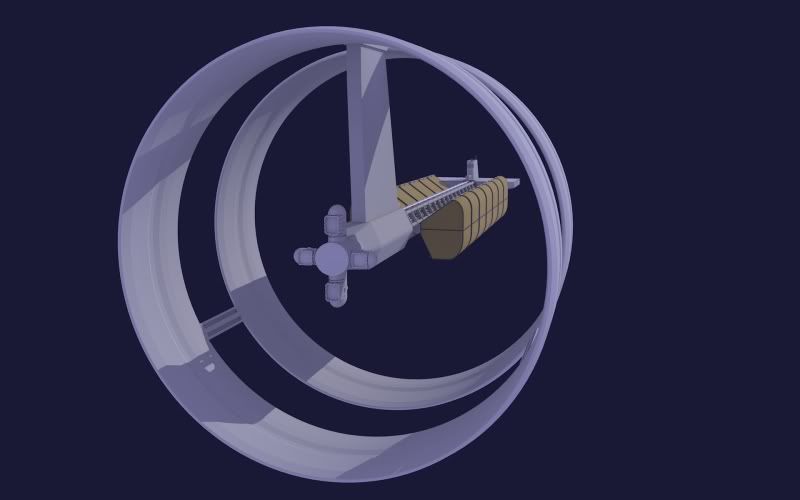

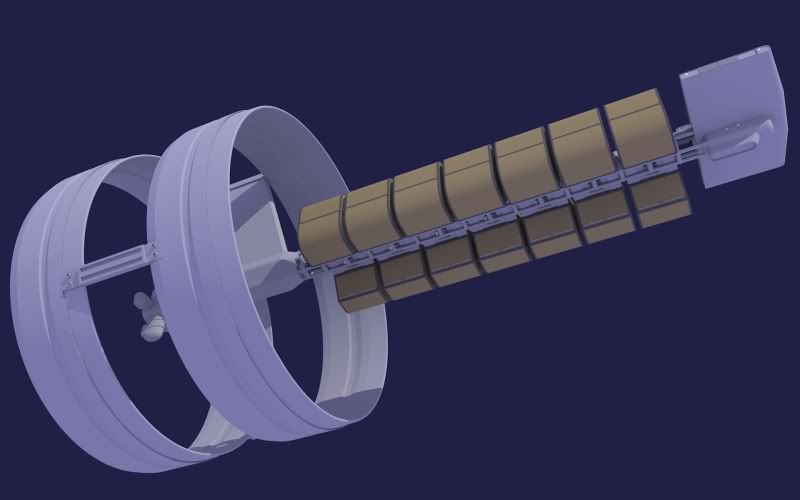

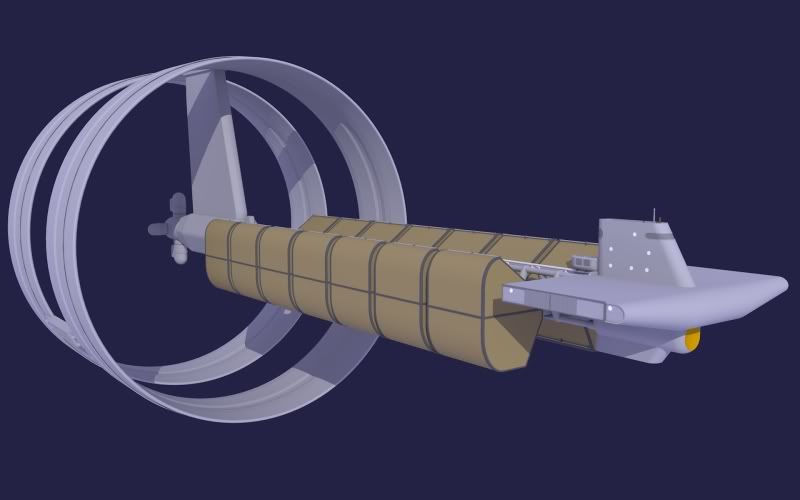

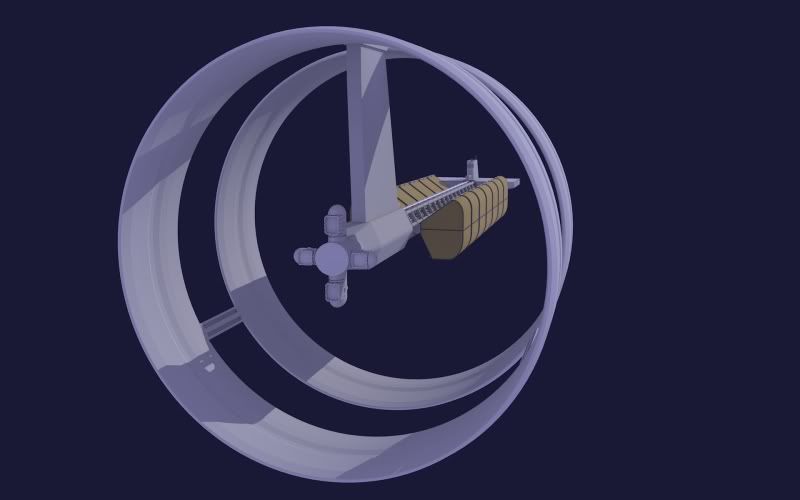

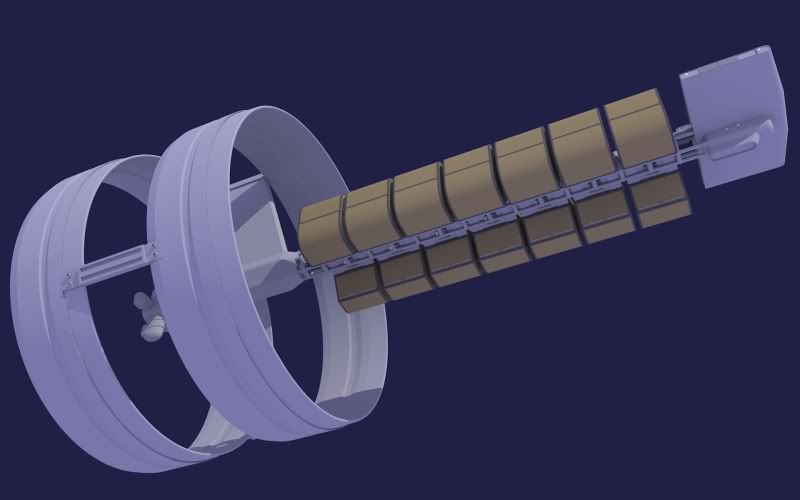

The DY-700 class cargo vessels are an off shoot of the XCV-300 project. What Starfleet saw as design problem in the maneuvering at warp issue, the cargo industry saw as a benefit. If the crews found it difficult to change course while at warp, there was less chance of "side trips" leading to more shipments arriving on time. The fact that the Annular propulsion system was based on proven Vulcan designs and better yet, more efficient was just icing on the cake.

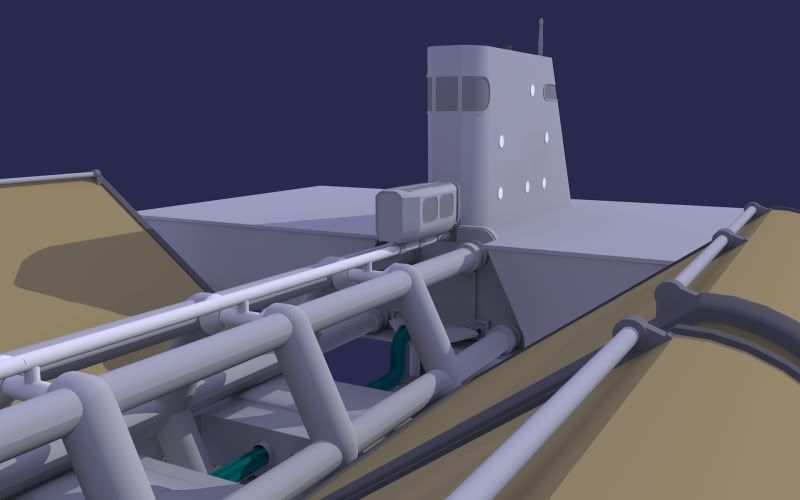

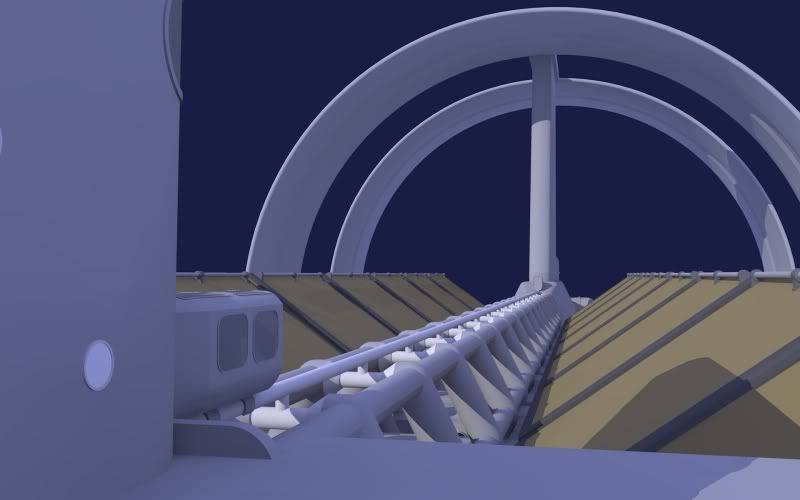

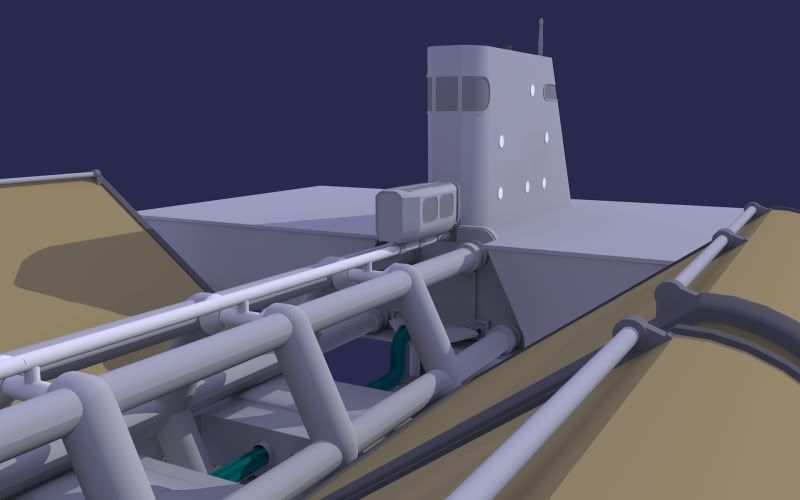

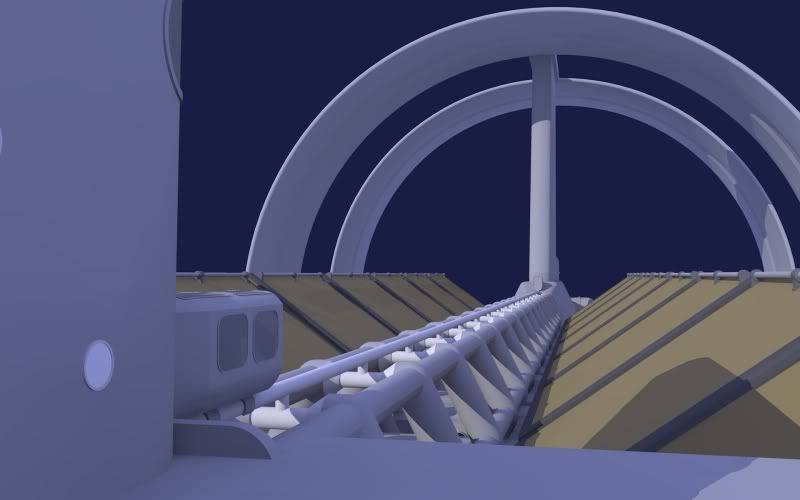

The design of the DY-700 reflects a modular construction method. The hammerhead crew modules, main cargo truss, and propulsion modules are built separately with final assembly in orbit. To save resources in construction instead of designing an access way leading from the crew area to the propulsion module it was decided to use a "turbo car" to get from one end of the ship to the other. This saved on life support and construction time/materials. In the starboard wing of the hammerhead there is a small bay for cargo workpods and a small 5 man shuttle.

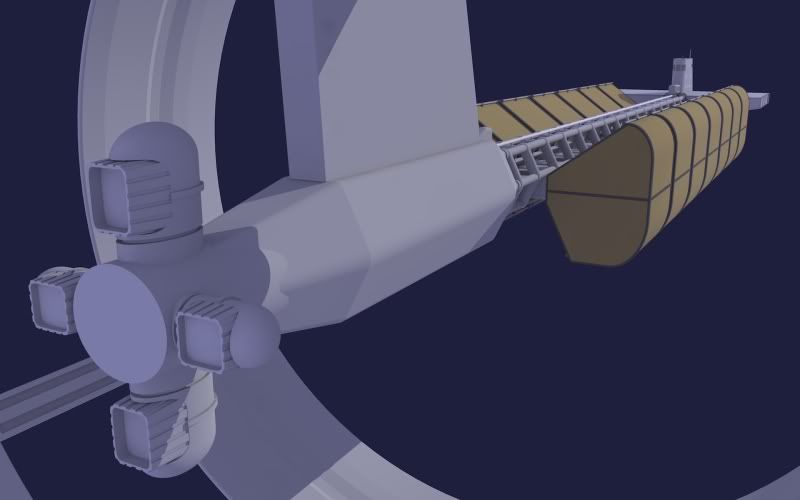

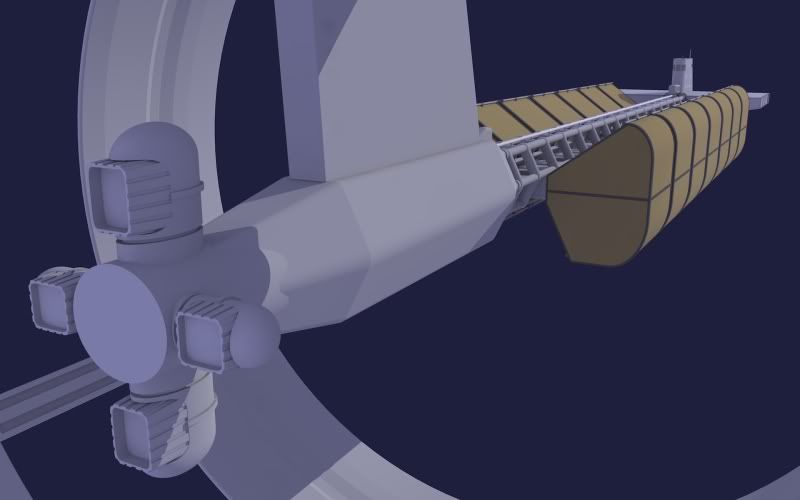

The impulse engines on the ship use a unique design that allowed the four outlet nozzles to swivel 120 degrees providing much improved maneuverability during yard operations.

The DY-700 proved itself a durable design with over 50 of the class being built and remaining in service for 63 years.

This was inspired by the XCV-300 Enterprise from the new SOTL calendar and of course, the DY-100.

Questions and comments always welcome.

The DY-700 class cargo vessels are an off shoot of the XCV-300 project. What Starfleet saw as design problem in the maneuvering at warp issue, the cargo industry saw as a benefit. If the crews found it difficult to change course while at warp, there was less chance of "side trips" leading to more shipments arriving on time. The fact that the Annular propulsion system was based on proven Vulcan designs and better yet, more efficient was just icing on the cake.

The design of the DY-700 reflects a modular construction method. The hammerhead crew modules, main cargo truss, and propulsion modules are built separately with final assembly in orbit. To save resources in construction instead of designing an access way leading from the crew area to the propulsion module it was decided to use a "turbo car" to get from one end of the ship to the other. This saved on life support and construction time/materials. In the starboard wing of the hammerhead there is a small bay for cargo workpods and a small 5 man shuttle.

The impulse engines on the ship use a unique design that allowed the four outlet nozzles to swivel 120 degrees providing much improved maneuverability during yard operations.

The DY-700 proved itself a durable design with over 50 of the class being built and remaining in service for 63 years.

This was inspired by the XCV-300 Enterprise from the new SOTL calendar and of course, the DY-100.

Questions and comments always welcome.